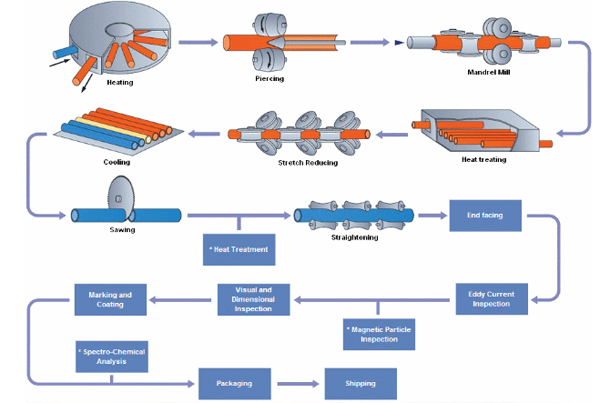

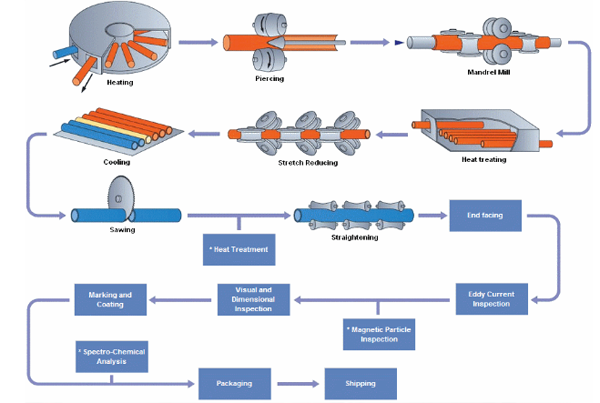

In the Mandrel Mill Process, a solid round (billet) is used. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube. The mother tube is reheated and further reduced to specified dimensions by the stretch reducer. The tube is then cooled, cut, straightened and subjected to finishing and inspection processes befor shipment.

* Note: Processes marked by an asterisk are conducted specification and/or customer requirements

Mannesmann plug mill process

Plug Mill Process, a solid round (billet) is used. It is uniformly heated in the rotary hearth heating furnace and then pierced by a Mannesmann piercer. The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness. The rolled tube simultaneously burnished inside and outside by a reeling machine. The reeled tube is then sized by a sizing mill to the specified dimensions. From this step the tube goes through the straightener. This process completes the hot working of the tube. The tube (referred to as a mother tube) after finishing and inspection, becomes a finished product.

Contact: Mr. Wang

Phone: +86-391-6660197

E-mail: mandrelshaft@gmail.com

Whatsapp:

Add: Dongzhang Village, Chengliu Town, Jiyuan City 459000